Noise Surveys and Abatement Services

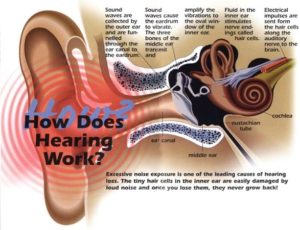

Sound is described as vibratory energy that takes the form of sound waves. Sound waves are funneled into the ear canal and vibrate the ear drum. This vibration causes pressure that moves the three smallest bones in the human body, the hammer, anvil and stirrup. The movement of these bones causes the fluid in the cochlea (ear center) to move, which in turn, make the hair follicles in the cochlea sway. This movement sends sensations to the auditory nerve, which send impulses to the brain. The brain then translates these impulses into the sounds that we know as hearing. Exposure to high noise levels, over time, destroy the hair follicles in the cochlea causing tinnitus (ringing in the ear) and hearing loss.

Sound is described as vibratory energy that takes the form of sound waves. Sound waves are funneled into the ear canal and vibrate the ear drum. This vibration causes pressure that moves the three smallest bones in the human body, the hammer, anvil and stirrup. The movement of these bones causes the fluid in the cochlea (ear center) to move, which in turn, make the hair follicles in the cochlea sway. This movement sends sensations to the auditory nerve, which send impulses to the brain. The brain then translates these impulses into the sounds that we know as hearing. Exposure to high noise levels, over time, destroy the hair follicles in the cochlea causing tinnitus (ringing in the ear) and hearing loss.

O SHA’s Hearing Conservation Standard requires that all companies with potential high noise determine if employees are being exposed to noise in excess of acceptable levels. If it is found that employee noise exposure is equal to or exceeds OSHA’s action level, it is required that a hearing conservation program be developed and implemented. At a minimum, the program must identify all high noise areas and equipment, and address noise monitoring, employee notifications, engineering and administrative controls, hearing protection, audiometric testing, training, and record keeping.

SHA’s Hearing Conservation Standard requires that all companies with potential high noise determine if employees are being exposed to noise in excess of acceptable levels. If it is found that employee noise exposure is equal to or exceeds OSHA’s action level, it is required that a hearing conservation program be developed and implemented. At a minimum, the program must identify all high noise areas and equipment, and address noise monitoring, employee notifications, engineering and administrative controls, hearing protection, audiometric testing, training, and record keeping.

It is always best to start by conducting a noise survey, which includes taking noise measurements throughout a facility. Noise surveys are relatively inexpensive and provide useful information such as the identification of equipment and processes that are generating high noise, employees that may be exposed to high noise, and the need for engineering and administrative controls. If there is a potential for employee exposure to high noise, personal dosimeter measurements may be needed.

Total Environmental & Safety, LLC’s (Total) associates include Certified Industrial Hygienists (CIH) and other certified safety professionals trained and experienced in: 1) hazard assessments and identification, 2) noise and dosimeter measurement collection and evaluation, 3) program development and implementation, and 4) employee training. This broad experience allows us the ability to offer turn-key solutions in a cost effective and timely manner.